POSITIVE ASPECTS:

• The installation length is shorter by 10-20 meters compared to the IECP.

PRINCIPLE OF OPERATION:

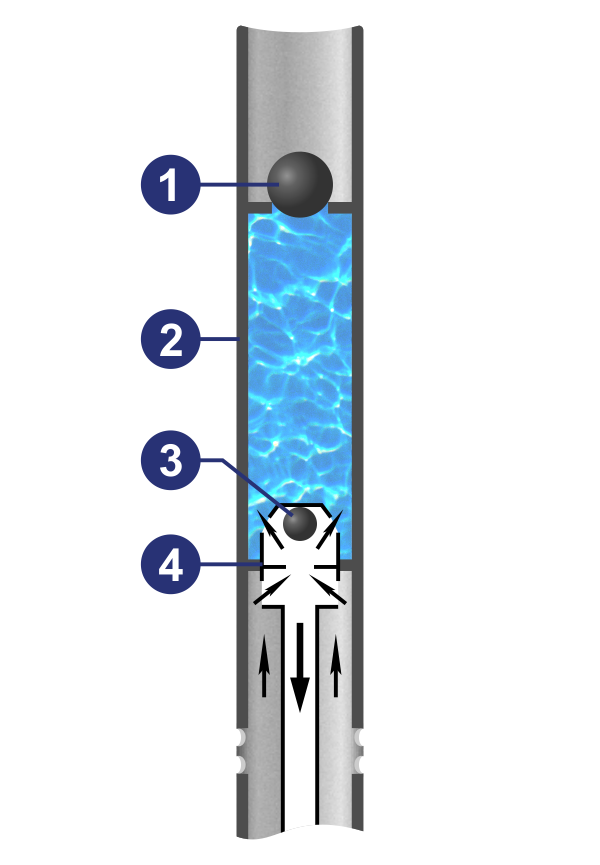

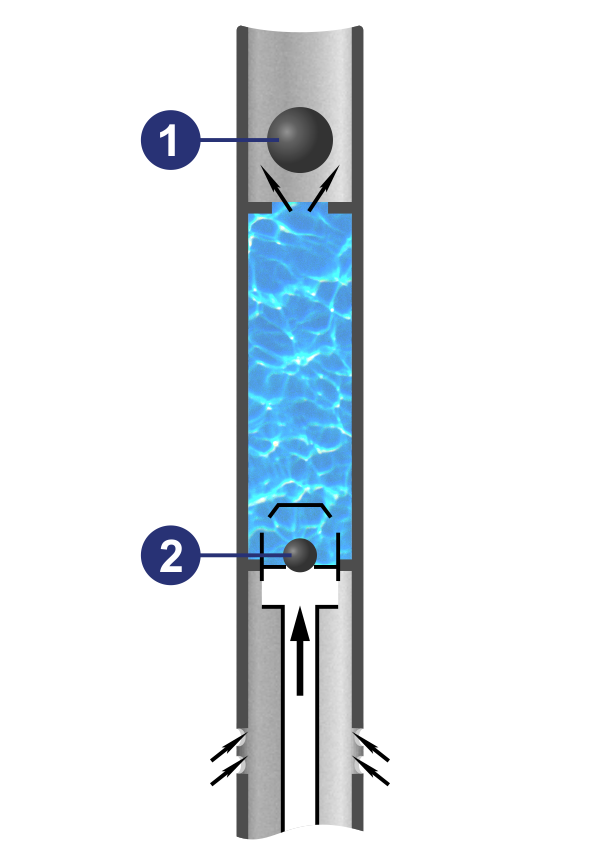

The linear motor is an electric machine, the principle of which is based on the use of energy of a running magnetic field.

In the linear motor there are no units for converting rotational motion into translational-return. The running magnetic field induces an electromotive force that creates a pulling force, moving the motor slider and the pump plunger without the use of sucker rods.

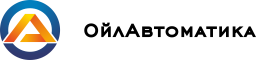

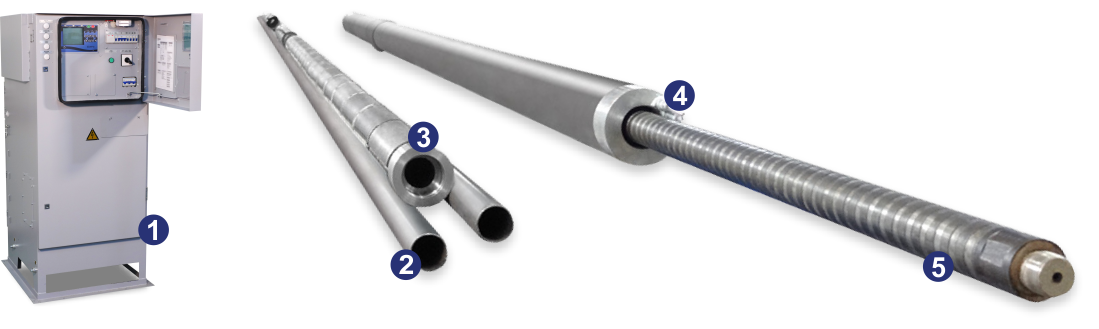

PLUNGER UNIT WITH LINEAR MOTOR CONSISTS OF:

1. Control station of «IRZ TEK» LLC;

2. Boosting transformer (OIL-FLOODED TRANSFORMER);

3. Plunger pump;

4. Linear valve submersible electric motor with submersible telemetry unit.

In the functionality of the control station used all the developments implemented in the intelligent control stations of the sucker rod pump «IRZ TEK» LLC taking into account the specifics of the linear motor control.

Installation of electric centrifugal pump (ECP) in periodic mode:

• Failure to reach production potential, problems with operating mode control

• Degradation of pressure-flow characteristics of ECP at high viscosity of the mixture

Installation of downhole sucker rod pump (IDSRP):

• Restriction on the depth of descent and curvature-failure of the production potential

• Ground metal capacity (rocking machine, pile field) and underground (pumping rods) equipment

• Increased environmental and technological risks during operation

• Reduction of overall efficiency by means of a rod column and a wedge-belt transmission

Installation of sucker rod screw pump (ISRSP) with surface drive:

• Restriction on the depth of descent and curvature-failure of the production potential

• Problems with the selection of elastomer material

• Low maintainability of the pump

Installation of electric screw pump (IESP) with submersible drive:

• Problems with the selection of elastomer material

• High value

• Low gear reliability

| SRP | ECP | PULM | |

|---|---|---|---|

| Productivity (m3/day) | <30 | >15 | <30 |

| Descent depth (m) | <2000 | <3000 | <3000 |

| Operational mode | constant | intermittent | constant |

| Specific energy consumption (kW/t) | 20 | 10 | 8 |

| The arrangement of the wellhead | demand | nonexistent | nonexistent |

| Substitutability | yes | nonexistent | yes |

| PULM (117mm) | 20, 35, 50 kW/t |

| Pump (plunger diameter) | 32, 38, 44, 57 mm |

| CS | 380V, 660V, 990V |

| TMS | Universal Digital TMS |

The commercialization of the development was funded by the Foundation for Assistance to Small Innovative Enterprises of the Russian Federation

Phone:

Address:

Email: